Food processing

Using technology to improve efficiency, accuracy and speed

Time to upgrade?

We’ll help you stay ahead of the competition

Machine vision has revolutionized sorting in the food industry, but there’s still plenty of room for improvement and innovation. Horizon Imaging specializes in upgrading software and electronics for greater efficiencies or to meet your specifications. Custom-designed upgrade packages may include:

- Cameras

- Image-acquisition boards

- Software algorithms

- Ejector electronics

Case studies

See how we developed a system for sizing onions and a system for locating candy on a printer bar.

Put our expertise to work for you

The engineers at Horizon Imaging have extensive experience, expertise and resources in the following areas

Optical engineering

- Cameras

- Lighting technology

Real-time embedded software

- Image acquisition with frame grabbers

- High-speed image processing

- Custom classification algorithms

Ejection or separation

- Mechanical and electrical design of ejection device

- Integration to ejection devices you provide

User interface

- Intuitive and elegant touchscreen interfaces

- Database design

- Communication with external devices or sensors in your plant

Mechanical design

- Packaging for computers, power supplies and other electronics

- Product presentation

- Sanitation

- Mechanical interfaces to equipment in your plant

Challenging engineering problem? Contact us today.

Case study

ONION SIZING

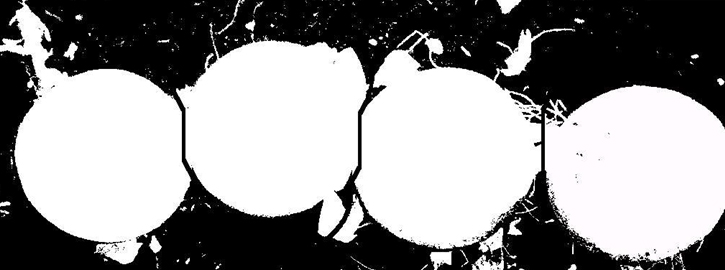

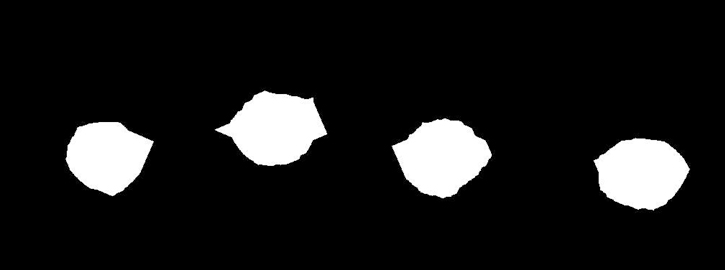

Four touching onions Moving along a belt, each onion must be examined and measured. The challenge: to separate touching pieces and ignore artifacts, including tops, tails and loose skin. This must be done in real time.

Four touching onions Moving along a belt, each onion must be examined and measured. The challenge: to separate touching pieces and ignore artifacts, including tops, tails and loose skin. This must be done in real time.

Color-segmented image Color segmentation separates the foreground (the onion, in this case) from the background. Overlap between background colors and dirt on the onions causes some noise in the segmentation.

Color-segmented image Color segmentation separates the foreground (the onion, in this case) from the background. Overlap between background colors and dirt on the onions causes some noise in the segmentation.

Object marker image In this step the objects are eroded by a given distance threshold using a Euclidean distance transform. Four markers result, where each marker corresponds to one of the onions.

Object marker image In this step the objects are eroded by a given distance threshold using a Euclidean distance transform. Four markers result, where each marker corresponds to one of the onions.

Watershed transform Starting with the four markers, a watershed transform separates onions that were touching in the original image.

Watershed transform Starting with the four markers, a watershed transform separates onions that were touching in the original image.

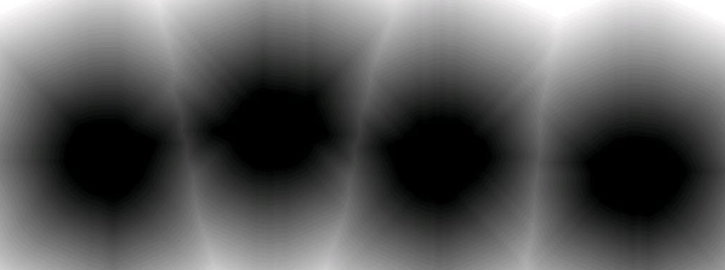

Perimeter pixels Here we see the perimeter pixels of the separated onions, as well as the perimeter pixels of artifacts. The artifacts include tops, tails, loose skins and noisy background. We want only those perimeter pixels that belong to the circular portions of each onion.

Perimeter pixels Here we see the perimeter pixels of the separated onions, as well as the perimeter pixels of artifacts. The artifacts include tops, tails, loose skins and noisy background. We want only those perimeter pixels that belong to the circular portions of each onion.

See how we do it

Click the numbered tabs to walk through our solution for sizing onions.

Case study

FINDING LOCATION OF CANDY FOR INSPECTION

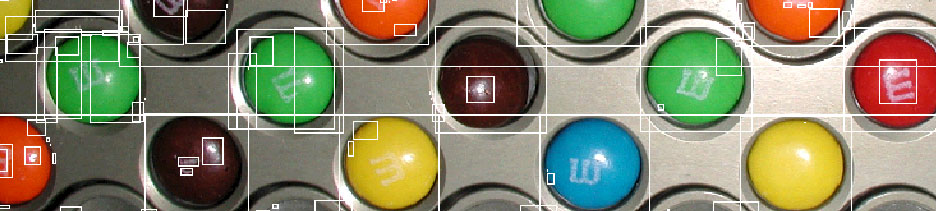

Printer bar How can you use machine vision to qualify objects? Here we see candy on a printer bar. First we need to find each object zone, excluding objects on the edge of the image.

Printer bar How can you use machine vision to qualify objects? Here we see candy on a printer bar. First we need to find each object zone, excluding objects on the edge of the image.

Approximate size

We start by overlaying a disk (pink circle) on one of the objects. The disk can be manually dilated or eroded until it is approximately the size of an object we care about. We then start an automatic template builder.

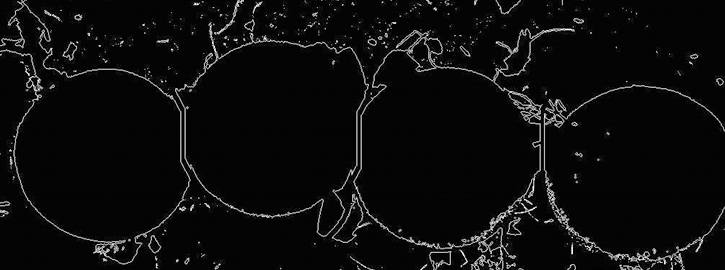

Canny edge detector

A simple way to determine the location of an object is to use an edge detector to find sharp gradients in an image. Here rectangles mark objects found with a Canny edge detector. We throw away rectangles that are out of range to our original disk size.

Accepted rectangles

Here is the result of the Canny edge detector for acceptable rectangles. Finding the location of each candy saves tedium for an operator.

See how we do it

Click the numbered tabs to walk through our solution for finding candy for inspection on a printer bar.