Lumber & wood products

Grading, measuring, serializing and quality control

Put our expertise to work for you

The engineers at Horizon Imaging have extensive experience, expertise and resources in the following areas

Optical engineering

- Cameras

- Lighting technology

Real-time embedded software

- Image acquisition with frame grabbers

- High-speed image processing

- Custom classification algorithms

Ejection or separation

- Mechanical and electrical design of ejection device

- Integration to ejection devices you provide

User interface

- Intuitive and elegant touchscreen interfaces

- Database design

- Communication with external devices or sensors in your plant

Mechanical design

- Packaging for computers, power supplies and other electronics

- Product presentation

- Sanitation

- Mechanical interfaces to equipment in your plant

Challenging engineering problem? Contact us today.

Case study

READING VENEER SERIAL NUMBERS

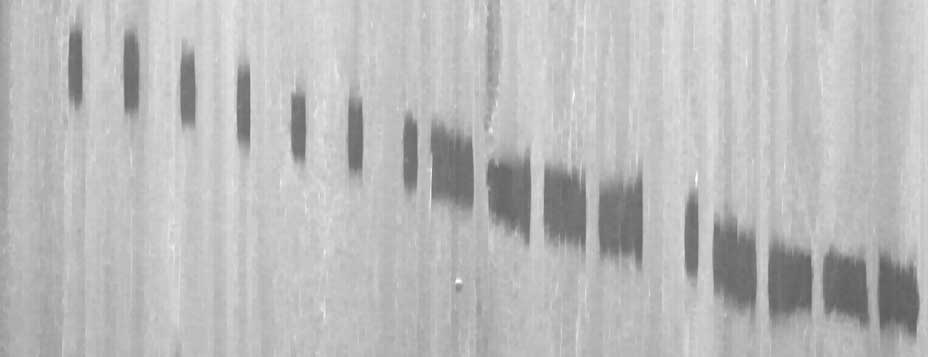

Veneer serial numbers Reading dark-ink serial numbers on plywood veneer isn’t as easy as it might seem. Challenges include changes in belt speed, light and veneer orientation. In this example, the veneer wasn’t straight when inked.

Veneer serial numbers Reading dark-ink serial numbers on plywood veneer isn’t as easy as it might seem. Challenges include changes in belt speed, light and veneer orientation. In this example, the veneer wasn’t straight when inked.

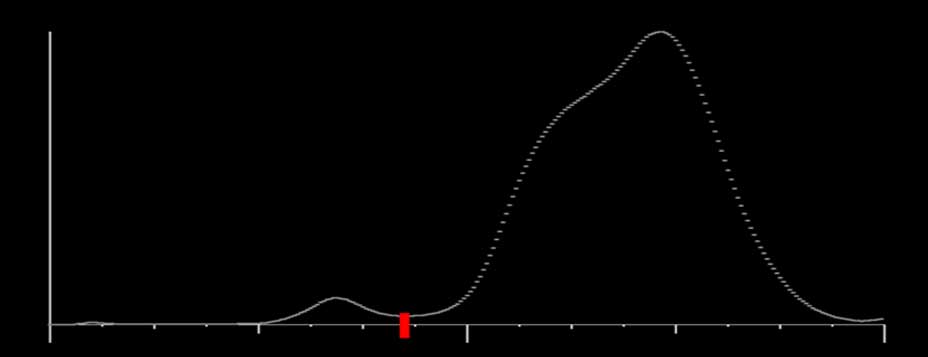

Lighting variance First we histogram the grayscale image. Here you see two humps. The larger hump is the light-colored veneer, and the smaller hump is dark spots on the veneer. Depending on lighting, these two humps can shift around. The smaller hump is what we’re interested in. It contains ink marks as well as other darker artifacts, such as knots. For thresholding, we’ll pick a value just past the dark hump shown by the red mark.

Lighting variance First we histogram the grayscale image. Here you see two humps. The larger hump is the light-colored veneer, and the smaller hump is dark spots on the veneer. Depending on lighting, these two humps can shift around. The smaller hump is what we’re interested in. It contains ink marks as well as other darker artifacts, such as knots. For thresholding, we’ll pick a value just past the dark hump shown by the red mark.

Size variance Two things improve the spatial aspects of the image. First, we sub-sample the image as it’s acquired. Using an encoder, we can add or delete lines to approximate an image. Second, we rescale the image, using Intel Performance Primitives (IPP), to an exact number of lines per image. The image leader and trailer black regions are removed.

Size variance Two things improve the spatial aspects of the image. First, we sub-sample the image as it’s acquired. Using an encoder, we can add or delete lines to approximate an image. Second, we rescale the image, using Intel Performance Primitives (IPP), to an exact number of lines per image. The image leader and trailer black regions are removed.

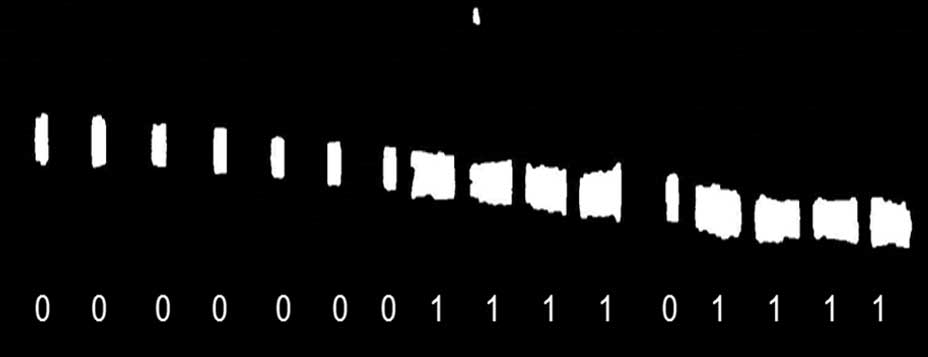

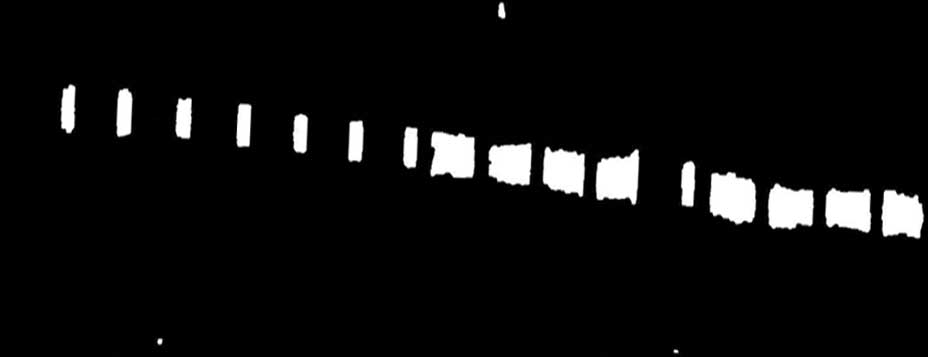

Binary image Some morphology is applied to close any holes in the ink blobs, and then we apply the threshold we found on slide 2 to the image. Any pixel brighter than our threshold is set to zero (black), and all the other pixels are set to a maximum value of 255 (white). We may have cracks and knots to deal with. Also, valid marker blobs may not be inked parallel to the edge of the veneer.

Binary image Some morphology is applied to close any holes in the ink blobs, and then we apply the threshold we found on slide 2 to the image. Any pixel brighter than our threshold is set to zero (black), and all the other pixels are set to a maximum value of 255 (white). We may have cracks and knots to deal with. Also, valid marker blobs may not be inked parallel to the edge of the veneer.

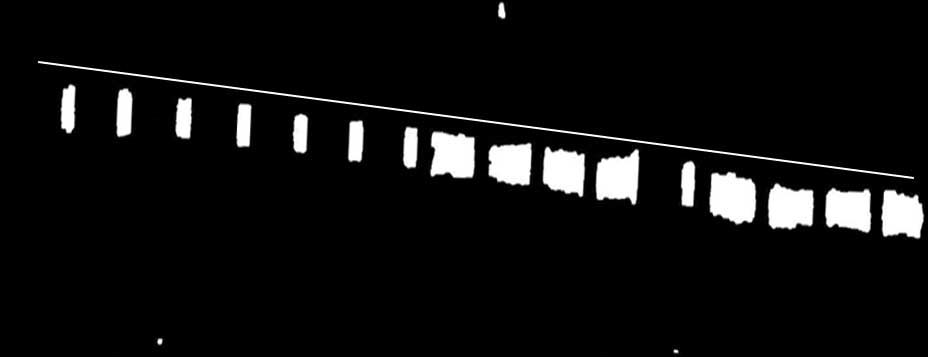

Filtering out artifacts The 16 ink blobs should form a rough line. A clustering algorithm estimates the slope and offset of the line through the ink-blob centroids. Any blob too far from the line is filtered out as an artifact. Many knots in the veneer will be filtered out as being too far from the line. Other knots will be filtered out based on their size. Some knots may be filtered out because of their aspect ratio.

Filtering out artifacts The 16 ink blobs should form a rough line. A clustering algorithm estimates the slope and offset of the line through the ink-blob centroids. Any blob too far from the line is filtered out as an artifact. Many knots in the veneer will be filtered out as being too far from the line. Other knots will be filtered out based on their size. Some knots may be filtered out because of their aspect ratio.

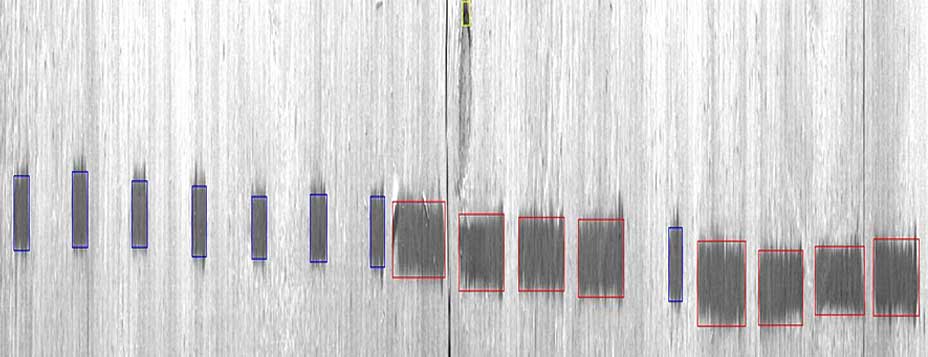

Brighter image with a knot The algorithm is now demonstrated on a plywood image with much brighter light levels. The algorithm adapts to changing light levels and correctly identifies eight dots and eight dashes. The dots and dashes are highlighted with blue and red rectangles, respectively. A knot is also filtered out. The dark portion of a knot at the top center of the image is highlighted with a small yellow rectangle. This knot can be filtered out due to size or to the distance from the line formed by the other ink blobs.

Brighter image with a knot The algorithm is now demonstrated on a plywood image with much brighter light levels. The algorithm adapts to changing light levels and correctly identifies eight dots and eight dashes. The dots and dashes are highlighted with blue and red rectangles, respectively. A knot is also filtered out. The dark portion of a knot at the top center of the image is highlighted with a small yellow rectangle. This knot can be filtered out due to size or to the distance from the line formed by the other ink blobs.

See how we do it

Click the numbered tabs to walk through our solution for reading veneer serial numbers.